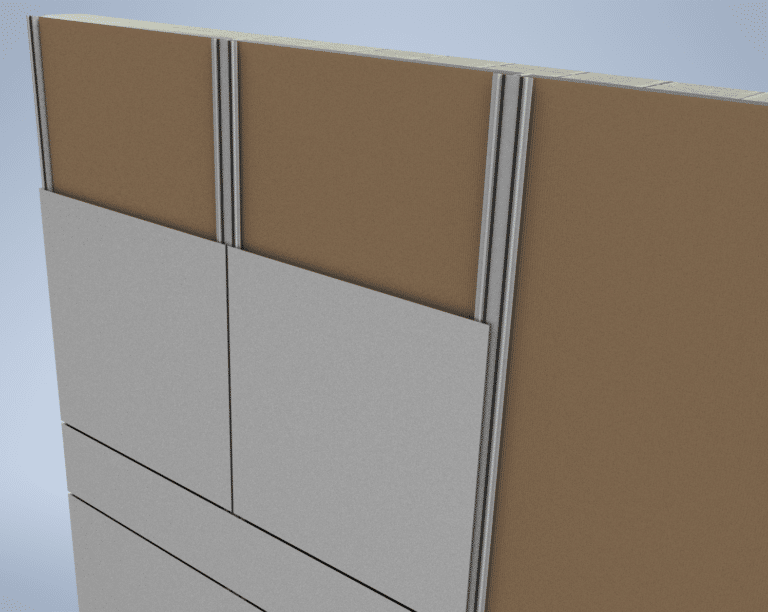

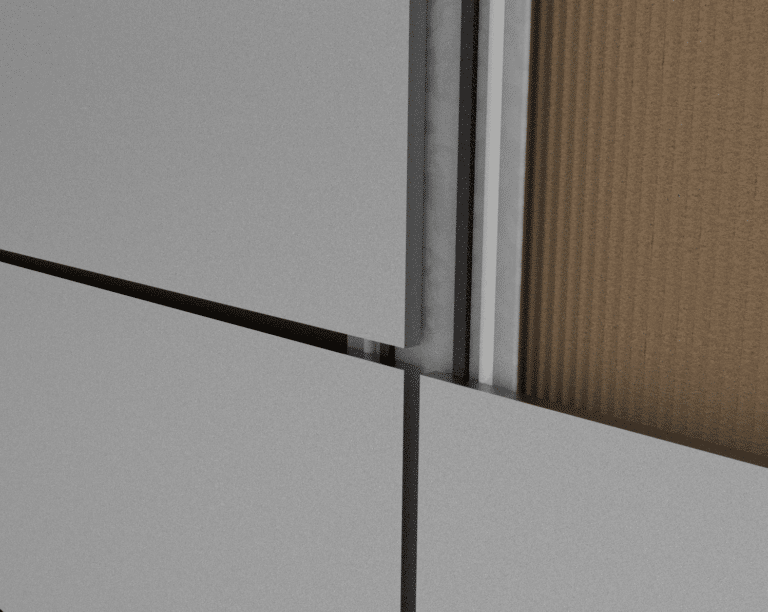

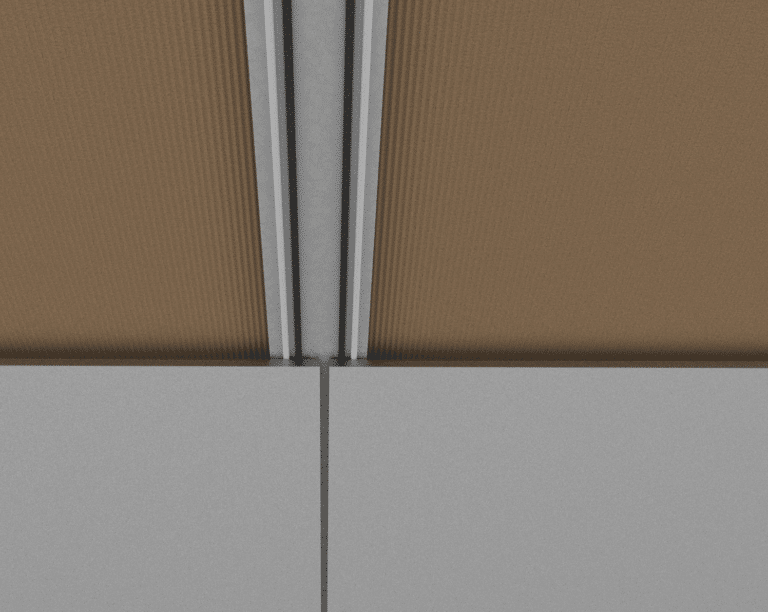

A Sticky Solution for Cladding Installation

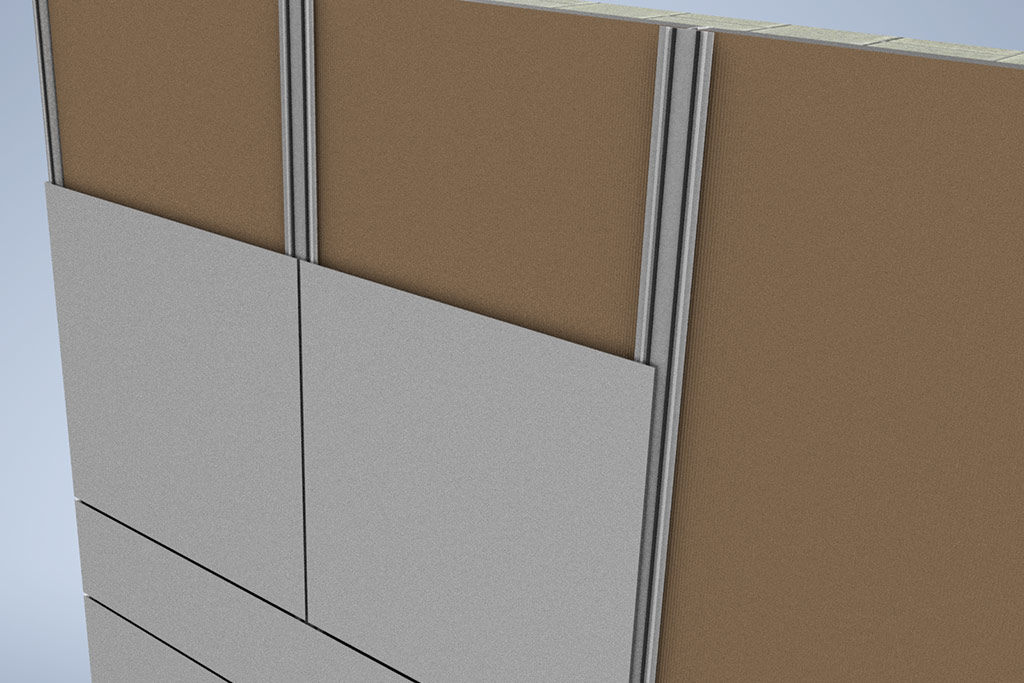

Adhesive cladding systems have become increasingly popular in construction due to their many advantages over traditional mechanical fasteners. These systems are used to attach cladding in a variety of applications, especially where thinner, lighter materials are used. These can include metal panels, fiber cement, high-pressure laminates (HPL), glass, and even some thin stone.

Adhesive technologies have advanced well beyond what has been available in the past, and should be seriously considered for cladding attachment. In this article, we will discuss why adhesive cladding systems have advantages over some typical cladding systems.

Fastener-Free Appearance:

Hidden fastener systems are incredibly popular for both exterior and interior cladding, and provide a clean, smooth appearance. They can also add some security to the installation since fasteners are not readily accessible. While hidden fastener systems are a great solution for thicker panel and heavier products, thinner cladding can struggle to accommodate the anchors required for installation. This typically results in an exposed fastener system.

Adhesive cladding systems eliminate the need for visible mechanical fasteners, resulting in a cleaner and more uniform appearance. The smooth surface creates a sleek and modern look that enhances the overall aesthetic of the building. This also eliminates the need to drill holes in the panels, which can act as stress risers in brittle panels like porcelain.

Faster Installation:

Adhesive cladding systems can be installed more quickly than mechanical fasteners. This is because the adhesive can be applied quickly and easily, without the need for drilling holes and inserting fasteners. Most systems are installed with a foam double-sided tape, and an adhesive. The foam tape provides the initial tack while the adhesive cures. In a well designed system, the installation time decreases significantly, which decreases total labor costs. The required skill to install the panels is also decreased by using adhesives.

Improved Durability:

Adhesive cladding systems can also provide improved durability compared to mechanical fasteners. This is because the adhesive creates a strong and secure bond that can withstand the stresses of expansion and contraction caused by temperature fluctuations. The foam tape and adhesive both have degrees of flexibility that fasteners just can’t match.

Increased Thermal Performance:

Adhesive cladding systems can help to improve the thermal performance of the cladding substructure by reducing the amount of conductive material. In a typical commercial installation with continuous insulation, a clip and rail concealed fastener system must be installed over furring z-girts, wall brackets, etc. In an adhesive system, the furring is still present, but the cladding can be installed directly onto the furring.

Reduced Noise Transmission:

Adhesive cladding systems can also help to reduce noise transmission from the exterior to the interior of the building. The adhesive and tape creates a continuous layer that increases the sound transmission coefficient for the entire system.

Reduced Maintenance:

Adhesive cladding systems require less maintenance than mechanical fasteners. This is because the adhesive creates a strong and durable bond that does not require tightening or replacement. Fasteners should be inspected for corrosion, and in some cases with exposed fasteners, UV degradation of rubber washers. These washers are used to provide a galvanic break between the fastener and panel, and when the washer breaks down, can result in corrosion or panel failure.

The adhesive and tape are both protected from UV exposure after installation, and won’t suffer from the same degradation.

Increased Design Flexibility:

Adhesive cladding systems offer increased design flexibility compared to mechanical fasteners. This is because the adhesive can be used to attach cladding materials to a variety of substrates, including concrete, masonry, metals, and even wood. Typical cladding support systems can become highly complicated to detail, and costly to install when accommodating unique designs. Adhesive systems can avoid some of those complications, since placement doesn’t rely on perfect fastener placement.

In conclusion, adhesive cladding systems can offer many advantages over traditional mechanical fasteners. As a result, these systems are becoming increasingly popular in construction and are likely to continue to grow in popularity in the coming years. Here at Monarch we’re happy to offer up a variety of compatible support systems for adhesive use, reach out to us to learn more about these systems, and how we can help you embrace adhesive cladding systems.

Why Choose Aluminum Slatwall Over Wood-Based Slatwall?

Why choose aluminum slatwall over wood-based slatwall?

Slatwall is used in many different environments, and we’re confident that everyone can benefit from durable, flexible, and resilient slatwall storage. It’s most commonly used for retail store fixtures, displays, and storage systems. It consists of a series of horizontal grooves into which various fixtures and accessories can be placed. The shape is mostly standardized across most manufacturers, including Monarch.

Slatwall is available in a variety of materials, including wood, plastic, and metal, with aluminum and wood being the two most commonly used materials. In this article, we will explore the benefits of choosing aluminum slatwall over wood slatwall.

Durability

One of the primary benefits of aluminum slatwall is its durability. Aluminum is a highly durable material that is resistant to warping, cracking, and fading. Unlike wood, which can be prone to water damage and rot, aluminum slatwall is impervious to moisture and can withstand extreme temperatures. This makes it an ideal material for use in areas with high humidity or temperature fluctuations, such as garages or warehouses.

This durability also comes into play with frequent changes of organization, where hooks would leave imprints on wood, aluminum slatwall remains unphased.

Strength

In addition to its durability, aluminum slatwall is also incredibly strong. It can support heavy items without sagging or bending, making it an excellent choice for storage systems and display fixtures. This is particularly important in a utility setting, where heavy or dense items would be stored. Most wood or particle board slatwall systems depend on aluminum inserts to add strength, but even then, they are much weaker than a full-aluminum system.

Maintenance

Aluminum slatwall is also incredibly low maintenance. Unlike wood slatwall, which requires regular sanding, staining, and sealing to maintain its appearance and prevent warping, aluminum slatwall is virtually maintenance-free. It does not require any special cleaning or maintenance procedures, and it is resistant to scratches and other forms of damage.

Monarch’s slatwall system comes standard with a clear anodized finish, which protects the aluminum from oxidation, but also yields a muted, even silver finish.

Aesthetics

Finally, aluminum slatwall offers a sleek and modern look that is perfect for contemporary retail environments. It is available in a variety of finishes, Monarch’s standard finish is the aforementioned clear anodized finish. We can also offer a more utilitarian mill finish, which is raw extruded aluminum. For a truly custom look, we can also work with you for a custom powdercoat finish.

Recyclability and Long Life

While aluminum itself has a larger carbon footprint than wood-based slatwall, it’s infinitely recyclable. It can also be reused, resized, and repurposed many times. Wood based slatwall systems are generally used once, and at the end of their service life, thrown away.

In conclusion, there are many reasons why someone would choose aluminum slatwall over wood slatwall. It is incredibly durable, strong, easy to install, low maintenance, and aesthetically pleasing. Whether you are looking to create a retail display, storage system, or any other type of fixture, aluminum slatwall is an excellent choice that will provide you with years of reliable service.

Visit our Slatwall Panel Systems page to learn more about our individual kits and available accessories.

Monarch Metal Inc. Now Accepting Custom Extrusion Requests

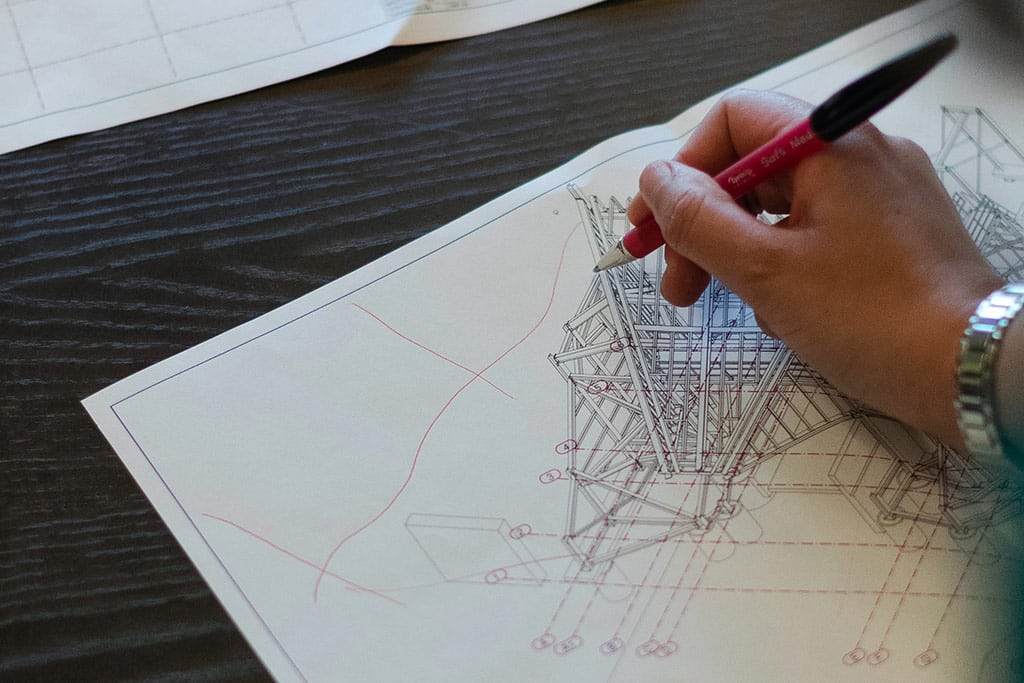

Monarch Metals has over 30 years of experience in the metal fabrication industry, and a major component of that experience lies in aluminum extrusion design and manufacturing. We’ve specialized in building products that solve common building and construction problems, and we would like to help our customers solve even more.

Here at Monarch Metal, we can help you develop a new custom extrusion to meet your needs.

Many times, extrusions can be designed to reduce the number of components needed, increase assembly speed, and add value. They’re used in a wide range of industries, and for good reason. You’ll see them utilized all around you, from household goods, to industrial machines.

Because we’re a small company, we know how difficult it can be to find manufacturing partners that will work on a small scale. One of our key strengths is the ability to extrude and process small lots of products. While most manufacturers will force you to buy large quantities of material, we can work with you to find the right starting point. That could be 500lbs of material, or 50,000lbs.

Extrusions on their own can create value, but we also have the ability to add even more value to you and your customers. This includes, but is not limited to:

- Punching Holes and Slots

- Drilling and Tapping Holes

- Bending

- Rolling

- Anodizing – Type I and Type II

- Custom Powdercoating – RAL Match

- Packaging

Once you’ve submitted your information, our product development team will review, research, and generate some initial ideas and concepts for your idea. During that process, we’ll channel our years of design, manufacturing, and assembly expertise to help solve your problem as efficiently as possible. After the initial review and plans are created, meeting with you and your team will be the next step. This is where we can make sure that we’re all on the same page, with all of the goals, constraints, and timing on the table.

The design and development process can last from a few weeks to a few months, depending on the complexity of the products. During that time, we’ll be in constant communication with you, and ensure that we’re meeting your expectations. We also have in-house prototyping options; those are typically free of charge as a sign of our partnership.

As the design and development process nears completion, we’ll provide you with finalized drawings, prototypes, and quotes for your product. Once the final design is approved, we’ll proceed with a tooling deposit, and subsequent tooling order. The tooling can generally be finished in 5-6 weeks, depending on our tool shop’s volume. First article parts will follow a couple of weeks after the tooling is complete.

We would love to hear more about your custom projects and ideas. Please visit our Custom Extrusion Request form, and let’s work together on a tailored solution for you.

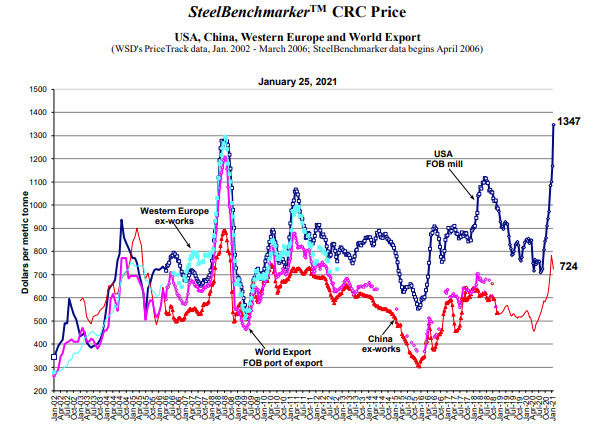

3 Reasons Steel Prices Skyrocketed in 2020

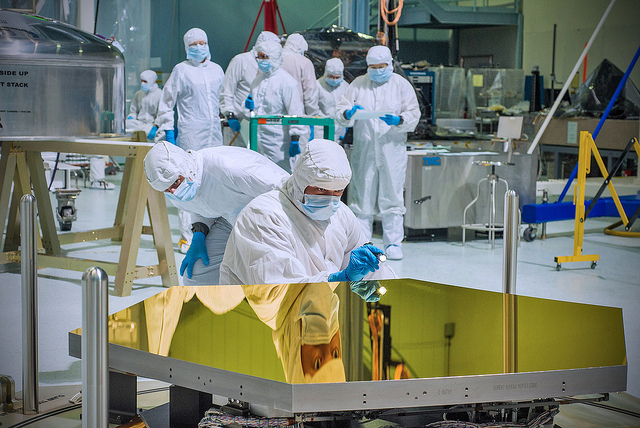

3D Printing Metal: The Advantages of Direct Metal Laser Sintering

5 Things You Didn’t Know About the Metal Fabrication Process

Basic metal fabrication involves the forming, shaping, or joining of metal. Typically, this happens through deforming or removing some portions of the raw material.

To many, metal fabrication may seem like a simple one or two step process. But the fact of the matter is, it’s much more detailed and comprehensive than simply pulling metal pieces off the inventory shelf. Here we’ll explore different aspects of metal fabrication to help you be more informed the next time you need to rely on the services of a fabricator:

…

5 Things You Didn’t Know About the Metal Fabrication ProcessRead More »

The Future of Manufacturing: Are We in the Midst of a Robot Takeover?

Robots often get a bad rap. Sci-fi novels and films have painted them as evildoers looking to take over our lives and our jobs. Pundits and politicians have largely done the same. But today’s innovative technology is proving that quite the opposite is true. Not only are robots creating jobs but they’re also making existing jobs more convenient. And, to top it all off, they work side-by-side with humans in a relatively peaceable manner.

They’re helping manufacturers turn bigger profits and making operations more efficient. They’re powerhouse machines that can work hour after hour without fatiguing to the point of needing a break. They don’t require salaries or benefits which prompts manufacturers to allocate money for other uses–such as hiring a robot operator or maintenance technician.

And because these machines can do repetitive tasks endlessly with a high degree of accuracy, they boost employees’ productivity in other areas that require a human touch.

Simply put: Robots act as a cost-effective and complementary component on the warehouse floor which makes for a higher quality product that consumers are compelled to by.

Types of Robots

While entertainment of the Sci-fi variety has conditioned us to believe that most or all robots take on human-like forms, the reality is that in manufacturing this simply isn’t true. Sure, some have arms and even “eyes†but for the most part, industrial robots are just…well, machines that help people get stuff done.

Here’s a look at some of the robot types on warehouse floors today:

- Cartesian Robots: Â Typically used in the automotive and auto component industries, Cartesian robots are noted for their linear movement and ability to move and carry heavy loads. Manufacturers rely on them for accuracy and repeatability when cutting drilling, stamping, or welding materials. Because of their versatility, especially in metal fabrication operations, these robots are gaining popularity in the metal and food/beverage packaging industries.

- Articulated Robots: Â Articulated robots are distinctly different than Cartesian robots in that they use rotating movement to achieve a full range of motion. They’re most often used in the automotive industry for assembling and material handling but they can also be used for welding, picking, cutting, and spraying materials.

- SCARA Robots:  Selective Compliance Assembly Robot Arms or SCARA robots have a parallel axis joint that acts as an arm and are used to for assembly, pick and place, and loading/unloading operations. In comparison to Cartesian robots, SCARA robots are cleaner and faster and more suited to high speed assembly. They’re often used in the automotive, electrical, and electronics industries.

Companies Making a Splash in Robotics

Many companies have happily adopted robotics as a key component in their business strategy. These are just a few:

Formerly known as Kiva Systems and acquired by Amazon in 2012, Amazon Robotics LLC uses robots to provide smarter, faster, and more consistent customer service. The robots, which move autonomously around the warehouse floor, are used to make warehousing operations like picking and packing quicker, easier, and more efficient all around.

While Amazon has no plans to share the technology with competitors, the Kiva Systems acquisition opened up a world of robotics possibilities for other companies to explore.

2. Kuka Robotics

Kuka Robotics produces a number of industrial robots designed specifically to aid manufacturers in production. Kuka strives to customize a manufacturer’s robotics experience by tailor-making robots to a specific need. Altogether, there are eight types of Kuka robots:

- Six axis robots

- Welding

- Cleanroom

- Shelf-mounted

- Palletizers

- Heat-resistant

- Press-to-press

- High accuracy

Each one comes equipped with a dependable, programmable PC-based system that manufacturers can use to streamline their production processes.

3. Rethink Robotics Â

Rethink Robotics provides manufacturers with robots that can easily adapt to real world variability. Using embedded cameras that work as “eyes,†these robots–called Baxter and Sawyer–can change applications quickly as well as ‘feel’ their way through any task. As such, they can perform a wide variety of tasks and work around obstacles that may hinder progress on a job.

All in all, technology has advanced to the point where industrial robots can be an asset to manufacturing companies. While robots are changing the way companies do business, they are largely acting as collaborators that can work side-by-side with humans to help meet or exceed goals. This isn’t a bad thing. In fact, it should be embraced as a mark of progress that helps companies and workers alike expand their knowledge of industry and the possibilities that lie ahead.

Job Training Programs: How 4 Companies are Closing the Manufacturing Skills Gap

Over the next decade, an estimated 3.4 million jobs will need to be filled in the manufacturing sector. The problem? Candidates with the right skills to fill those positions will be few and far between.

To close this skills gap, these four companies are taking matters into their own hands:

…

Job Training Programs: How 4 Companies are Closing the Manufacturing Skills GapRead More »

The Basics of Agile Manufacturing

So, let’s say you’ve implemented lean manufacturing principles, have achieved a certain level of success, and are now ready to make your manufacturing business even stronger. What’s the next step? Is there a next step after lean? The answer is simply: yes.

…

Is New Technology Fueling the New-Shoring Trend?

Innovations in technology are making it easier than ever to manufacture products right here at home. From 3D printing and computer aided design to the Internet of Things and data analytics, modern technology is transforming the way manufacturers think and create.

But something else is transforming, too: production. While many established companies have chosen to produce goods in lands far and away over the years, newly launched start-ups and independent manufacturers are using innovative technologies to keep production all American. This trend, called new-shoring, started to pick up just a few years ago and is now a way of business for many manufacturing newcomers.

…