Manufacturing Trends to Look Out for in 2016

There’s no question that the landscape of the manufacturing industry is changing fast. And as manufacturers ring in the New Year, it’s a good idea to take stock of what’s ahead of us. In 2015, we saw the rise of additive manufacturing, ‘smart’ factories, and more digitally conscious manufacturers. After a full year of exploring these three concepts in detail, manufacturers will have had enough exposure to successfully implement them in 2016.

Let’s take a look at how these concepts will inform manufacturing processes in the coming months:

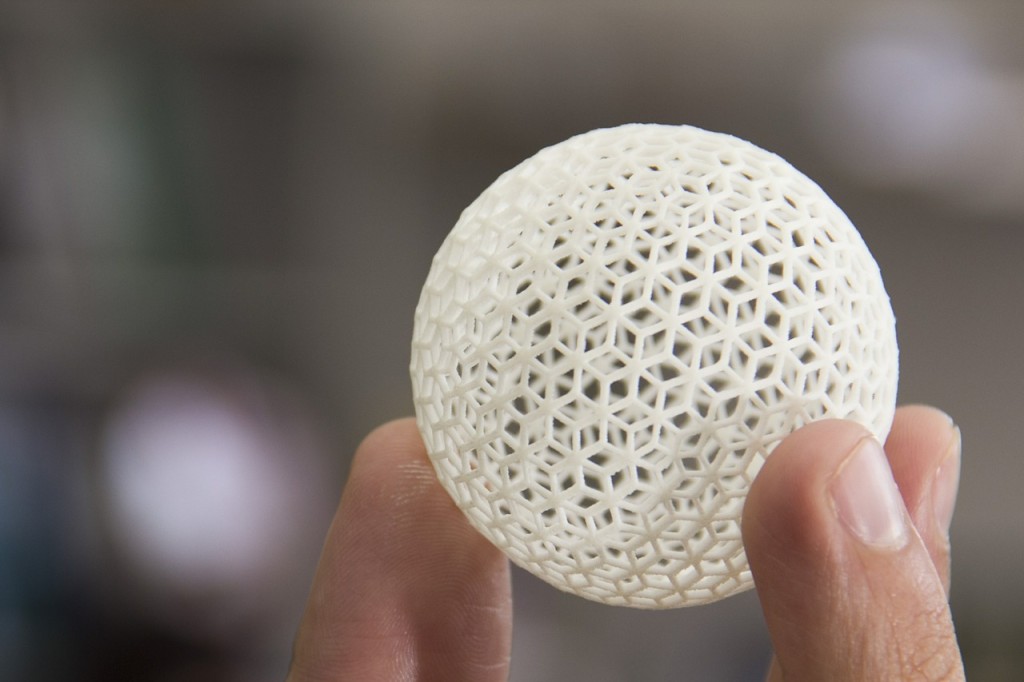

- E-commerce: Advanced technology like 3D printing has given manufacturers the ability to build and test prototypes at an incredibly rapid pace. But when greatness is achieved via additive manufacturing and other process, it can be costly to get the product out to the public. In 2016, manufacturing companies will find it easier to test the waters with the help of e-commerce platforms.

E-commerce allows manufacturing plants to produce based on demand. That means companies will no longer have to shell out big portions of their budget to keep inventory on hand or build new locations to expose the market to their products. Instead, manufacturers can offer the product on their e-commerce stores and use their resources only as orders come in. - Analytics: For many manufacturers, ‘analytics’ might seem like a term that only Millennials and computer geeks use at hipster-friendly startups. But as we saw in 2015, digital technology is changing the way manufacturers do business and it’s becoming increasingly obvious that some form of digital analytics needs to have a place in the industry.

Taking take steps toward digitizing your manufacturing business will put you ahead of the game. As your processes are digitized, you’ll have better access to pertinent information that can help you discover new ways to improve the business as a whole. In a digital environment, information about inventory, pricing, production, and shipping can all be synced to ensure the kind of efficiency and transparency that can be lost even with a paper trail.

This digitization can also save you from experiencing company downtime. Digital machinery is becoming the standard in the industry and for good reason. By using advanced analytics, these machines have the ability to scan and predict malfunctions and give you the opportunity to remedy problems before faulty machines halt production. - Personalization: Only recently have manufacturers become hip to the idea of personalization. As the demand for more personalized products becomes the norm in other industries, manufacturers have taken notice and, in turn, have taken steps toward incorporating that principle into their business models.

Although striving for precise personalization can change the pace of a business altogether, it’s things like E-commerce and advanced analytics that are making the transition that much easier.

No matter what 2016 brings, it’s clear that digitization is revolutionizing the manufacturing industry. And to keep up with changing times, companies are going to find it necessary to implement more modern and efficient processes to meet customer expectations.